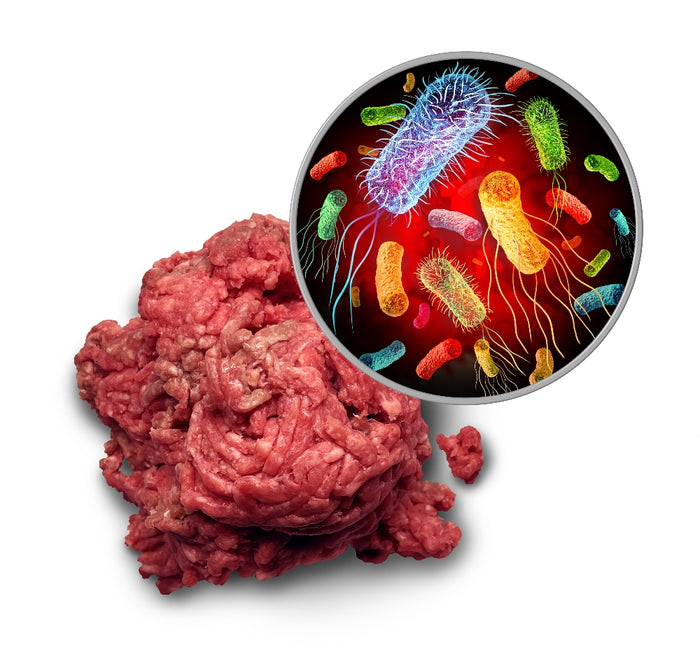

Revolutionizing Food Processing with Advanced Sanitization

Maintaining impeccable hygiene is paramount in meat and food processing, to prevent contamination and ensure consumer safety. Traditional chemical disinfectants often leave harmful residues, pose environmental concerns, and may lose effectiveness as microorganisms develop resistance. OmniLyte addresses these challenges by offering Anolyte Water, an electrolyzed water solution that serves as a powerful food contact surface sanitizer. It's proven to remove pathogenic bacteria, pesticide residue, mycotoxins, and fungal mold from raw materials and surfaces without compromising food quality or safety.

As with all other living organisms, harmful microbes require energy to survive. Anolyte Water destabilizes the immediate energy environment where microbes can live - thus eliminating them, with no risk of micro-organisms building up a tolerance to this charge-based technology (unlike traditional chemical-based approaches). By integrating OmniLyte's disinfectant water generators into processing lines, facilities can achieve superior sanitation, enhance product shelf life, and reduce reliance on hazardous chemicals. OmniLyte HOCL received a No Objection Letter for use not exceeding 200PPM in Canada and OmniSan Anolyte is EPA registered in the USA.

Residue-Free Disinfection

Research and studies show that Anolyte Water removes bacteria, viruses, yeasts, molds, spores, and fungi on contact surfaces without leaving harmful residues, ensuring both safety and quality in food products.

Enhances Food Safety

Many research and studies have shown that Anolyte removes pathogenic bacteria, reducing the risk of foodborne illnesses. It also eliminates pesticide residues and mycotoxins, ensuring cleaner raw materials.

Key Benefits

OmniLyte Certifications

We are here to help

Over a Decade of Experience

The OmniLyte team brings over a decade of hands-on experience with ECA technology. We offer expert consultation, on-site installation, and hassle-free maintenance services.

Equipment Spotlight

What Equipment Does My Operation Need?

We offer a free consultation to recommend the best generator for your industry application, considering factors such as water capacity, water sources, and your specific application.

OmniLyte’s HD-Series Generators are designed for industries requiring high-strength food contact surface sanitizers. By generating anolyte on-site, these systems eliminate the need for bulk chemical storage, reducing costs and improving workplace safety. The ELA-HD Series ECA Generators are one option well-suited for meat and food processing operations.

High-Concentration Disinfection

ELA-HD Series ECA Generator

ELA-HD-Series disinfectant water generators are designed for precise sanitation control and efficiency. It produces high-strength anolyte solutions consuming just 4 watts of energy per liter of 1,000 ppm anolyte.With adjustable chlorine concentrations between 1,000 and 7,000 ppm, it is a versatile and cost-effective alternative to traditional disinfection methods.

Installation Gallery

View all Reverse Osmosis SystemsMeat and Food Processing FAQs

How can we effectively reduce pathogens in meat processing without harsh chemicals?

How can we effectively reduce pathogens in meat processing without harsh chemicals?

Many studies suggest that electrolyzed water which can be produced by OmniLyte's Anolyte technology eliminates 95-99% of harmful pathogens safely and efficiently. Anolyte technology is safe for meat processing applications. It reduces spoilage, extends shelf life, and ensures the highest standards of hygiene in meat processing facilities!

What is Anolyte Water, and how does it function as a sanitizer?

What is Anolyte Water, and how does it function as a sanitizer?

Anolyte Water is an electrolyzed water solution produced through electrochemical activation, resulting in a potent disinfectant containing hypochlorous acid. It destabilizes microbial energy environments, effectively eliminating pathogens without harmful residues.

Is Anolyte Water safe for direct contact with food surfaces?

Is Anolyte Water safe for direct contact with food surfaces?

Yes, Anolyte Water is non-toxic and safe for use on food contact surfaces. It does not alter the taste, texture, or appearance of food products and leaves no harmful residues.

Is Anolyte approved for use in meat processing?

Is Anolyte approved for use in meat processing?

Yes! Health Canada has expressed no objection for the use of Anolyte as an antimicrobial aid for food processing use on red meat and poultry meat on specific conditions. OmniSan Anolyte is also an EPA registered non-porous surface disinfectant.

Is Hypochlorous Acid Approved for Use in the Meat Industry?

Is Hypochlorous Acid Approved for Use in the Meat Industry?

Hypochlorous acid is recognized by the FDA as a food-contact substance and is approved as an antimicrobial agent in ice for cooling various foods including meat and poultry, ensuring compliance and safety for food processors.

With Health Canada, HOCl is approved as an antimicrobial food processing aid on red meat and poultry under specific conditions. This ensures compliance with stringent national safety standards.

Is HOCl Approved by the EPA?

Is HOCl Approved by the EPA?

OmniSan Anolyte is an HOCl brand approved for use by EPA on non-porous hard surfaces, as a disinfectant, sanitizer and deodorizer.

How can Anolyte be used in red meat processing?

How can Anolyte be used in red meat processing?

Anolyte, electrolytically generated hypochlorous acid, can be applied to the surface of red meat carcasses up to 20ppm calculated as free available chlorine in an aqueous solution.

How can Anolyte be used in poultry processing?

How can Anolyte be used in poultry processing?

Anolyte is approved for use on poultry meat carcasses up to 50ppm calculated as free available chlorine in chiller water and/or aqueous solutions applied before immersion in a pre-chiller or chiller tank.

Can Anolyte be used for giblets?

Can Anolyte be used for giblets?

Yes. Under Health Canada, Anolyte is approved for use on the surface of giblets up to 35 ppm calculated as free available chlorine in an aqueous solution.

Can microorganisms develop resistance to Anolyte Water?

Can microorganisms develop resistance to Anolyte Water?

No, many studies and research conducted have shown that the unique mechanism of Anolyte Water prevents microorganisms from building resistance, ensuring consistent and reliable disinfection.

How is Anolyte Water produced on-site?

How is Anolyte Water produced on-site?

Anolyte Water is generated using OmniLyte's disinfectant water generators, which utilize water, salt, and electricity to produce the solution on-demand, eliminating the need for bulk chemical storage.

What are the environmental impacts of using Anolyte Water?

What are the environmental impacts of using Anolyte Water?

Anolyte Water is environmentally friendly, breaking down into harmless substances after use, thus reducing the ecological footprint associated with traditional chemical disinfectants.

Is HOCl approved for general sanitation?

Is HOCl approved for general sanitation?

Absolutely! OmniLyte HOCl has a Letter of No Objection from Health Canada for use as a sanitizer of food contact surfaces and a multi-purpose cleaner in various conditions. OmniSan Anolyte is another OmniLyte product, approved by EPA for use in the USA.

Have Questions?

Whatever your challenge, our team of experts can help you find the right water treatment system for your operation

Let's talk.