Our Commitment

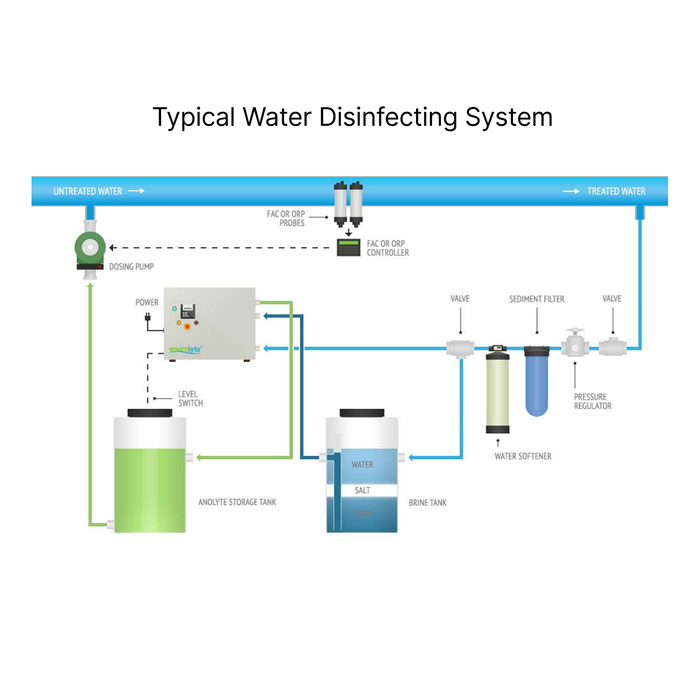

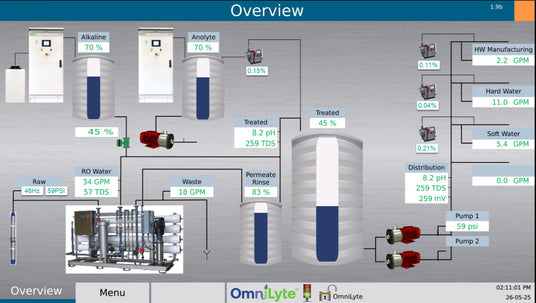

We are committed to continuous innovation in revolutionizing water treatment by integrating environmentally sustainable technologies. We integrate Programmable Logic Controllers, the Industrial Internet of Things, Real-Time Monitoring, and other future technology enhancements for efficiency, while reducing environmental impact.

Understanding ECA Technology

Electrochemical Activation (ECA) is a proven, science-backed technology used to create powerful and environmentally safe water disinfection solutions.

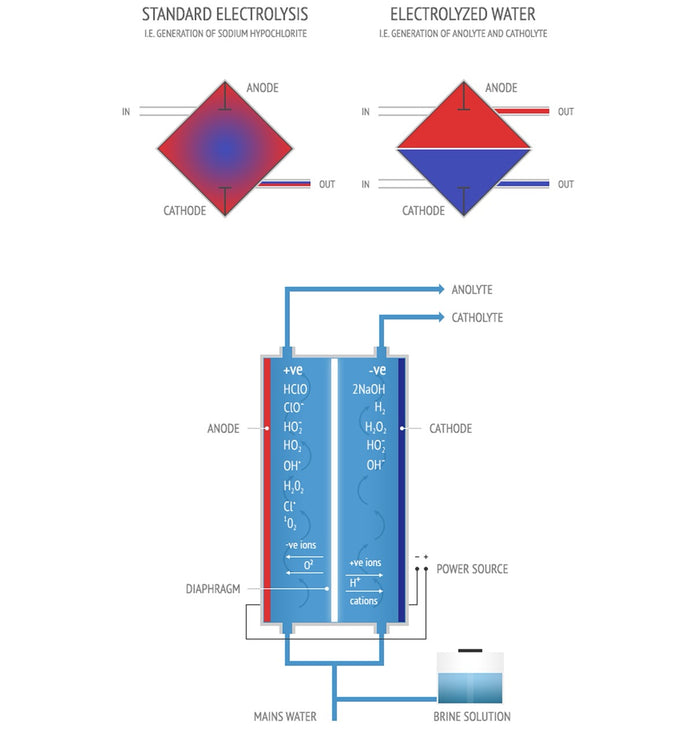

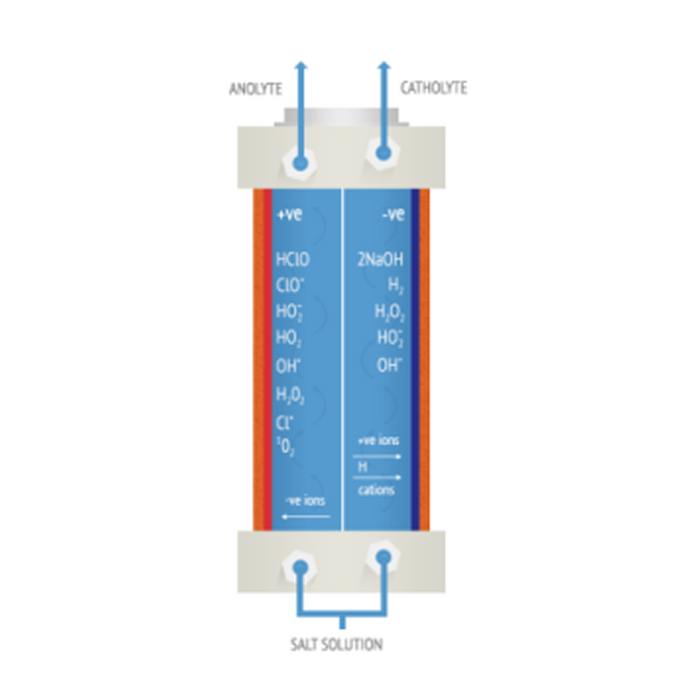

At the core of this process is electrolysis, where a low-voltage electrical current is applied to a diluted saltwater solution as it passes through a specially designed electrolytic cell. This triggers a controlled, non-spontaneous chemical reaction, transforming the solution into two distinct, non-toxic outputs:

- Anolyte: a disinfectant containing hypochlorous acid (HOCl), which many studies show is effective against bacteria, viruses, fungi, and biofilms.

- Catholyte: a gentle, alkaline cleaning solution containing sodium hydroxide (NaOH), with powerful cleaning and degreasing capabilities.

Anolyte and Catholyte are low-mineral, metastable solution, meaning they exist in a temporarily energized state that gives them increased chemical reactivity and enhanced disinfection. This is a key reason why they are highly effective at low concentrations and can outperform conventional chemicals.

Importantly, microorganisms do not develop resistance to HOCl - ensuring long-term, effective sanitation without the diminishing returns seen in some conventional disinfectants.

Electrolyzed water technology is safe for people, gentle on equipment, and the outputs are biodegradable - making it ideal for industries that demand reliable water disinfection systems without the environmental or operational risks of hazardous chemicals.

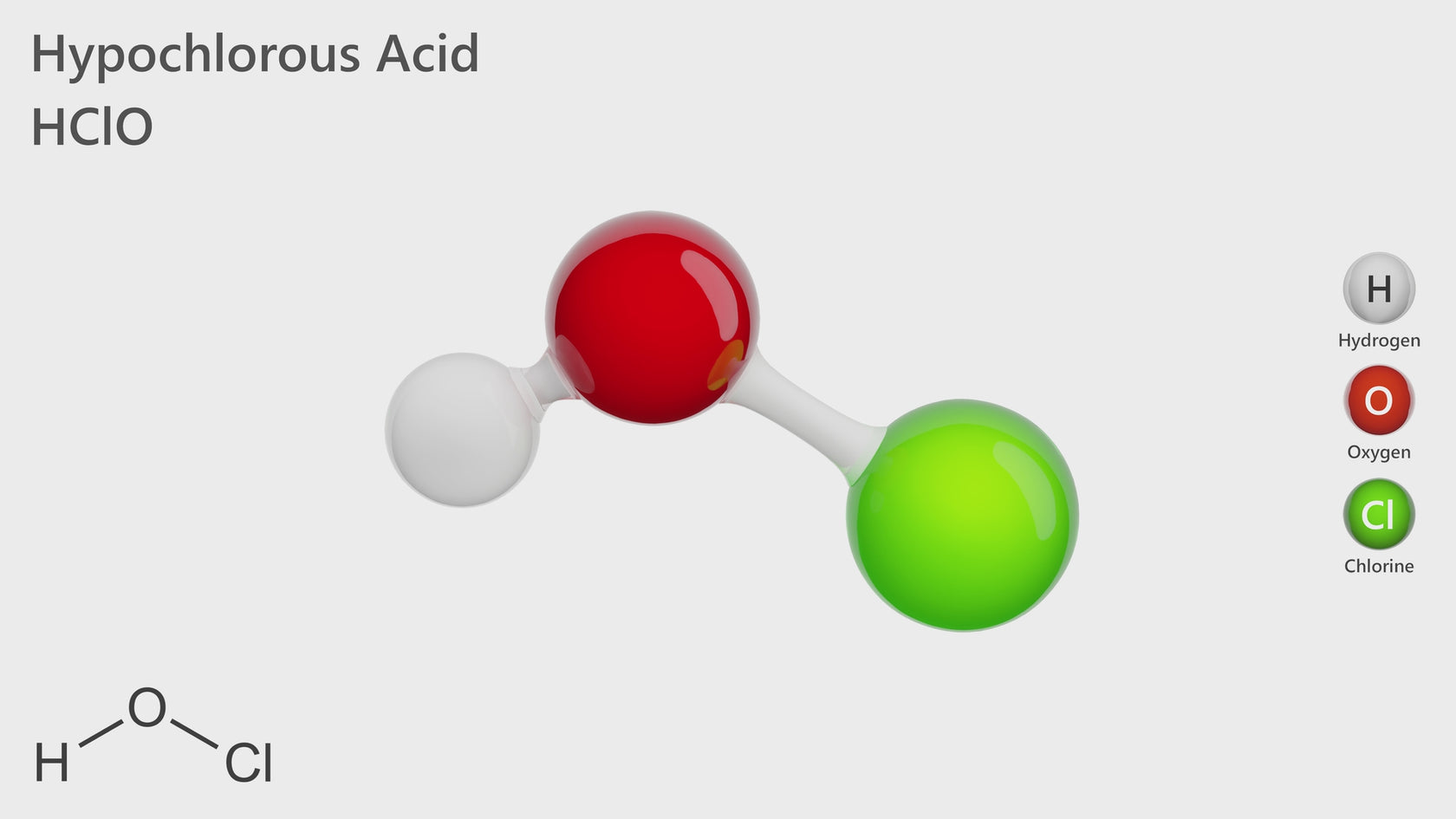

How Hypochlorous Acid Is Created

Producing hypochlorous acid (HOCl) involves a straightforward chemical process. It begins by combining carefully measured amounts of salt (sodium chloride) and water. When an electrical current is applied, the solution is split into two useful compounds through a process called electrolysis.

This electrochemical reaction is the foundation of electrolyzed water, allowing the production of safe, sustainable water treatment solutions without the need for harmful chemicals.

-

Hypochlorous Acid (HOCl)

A powerful, natural disinfectant, the same that the body's immune system produces to fight off pathogens. In ECA systems, HOCl is generated when the pH is properly controlled, resulting in a highly effective, non-toxic sanitation solution.

-

Sodium Hydroxide (NaOH)

A mild alkaline cleaner formed during the same process. It’s commonly found in household and industrial cleaning products, and in low concentrations, it serves as an effective degreaser.

What Makes OmniLyte's ECA Technology Unique

Patented Diaphragmatic Cell Design

Our proprietary diaphragmatic cell physically separates the anode and cathode chambers, preventing the reactive streams from mixing.

This ensures the pure production of hypochlorous acid, rather than reverting to less effective compounds like sodium hypochlorite, which commonly forms in unipolar or non-separated systems.

Download our Technical Brochure below to learn more about electro-chemically activated water.

Technological Innovations in our Equipment

We incorporate various technological innovations in our ECA Generators to enhance the efficiency, safety, and sustainability of our water treatment solutions.

Here are some of the key advancements that may be present in our systems:

Smart Automation & PLC Control

Our state-of-the-art PLC systems provide precise, adaptive automation tailored for energy-efficient industrial applications. Key benefits include:

- Optimized energy consumption for reduced carbon footprint

- Seamless integration with existing infrastructure

- Robust safety protocols for sustainable operations

Industrial Internet of Things (IIoT) for Eco-Efficiency

By embedding IIoT into our solutions, we empower industries with real-time data analytics and predictive insights to optimize resource use. Features include:

- Remote monitoring for reduced operational waste

- Data-driven decision-making for sustainable growth

- Integration with smart grids for enhanced energy efficiency

Cloud & Edge Computing for Sustainable Management

OmniLyte leverages cloud-based and edge computing solutions to streamline industrial operations with a focus on sustainability. Advantages include:

- Cloud-driven insights for improved resource allocation

- Edge computing for real-time, low-energy processing

- Secure, scalable solutions tailored for green initiatives

Partner with us for Sustainable Solutions

Transform your industry with OmniLyte’s sustainable and unique water treatment technologies. Contact us today to explore how we can drive efficiency while protecting the environment.

Why Partner With OmniLyte?

OmniLyte Certifications

Electrolyzed Water - The Future of Agriculture

Have Questions?

Whatever your challenge, our team of experts can help you find the right water treatment system for your operation

Let's talk.