ECO Ionizer Generator

(FOR STOCK AVAILABILITY, LEAD TIME, OR PRICING, PLEASE CALL +1 (800) 419-5707)

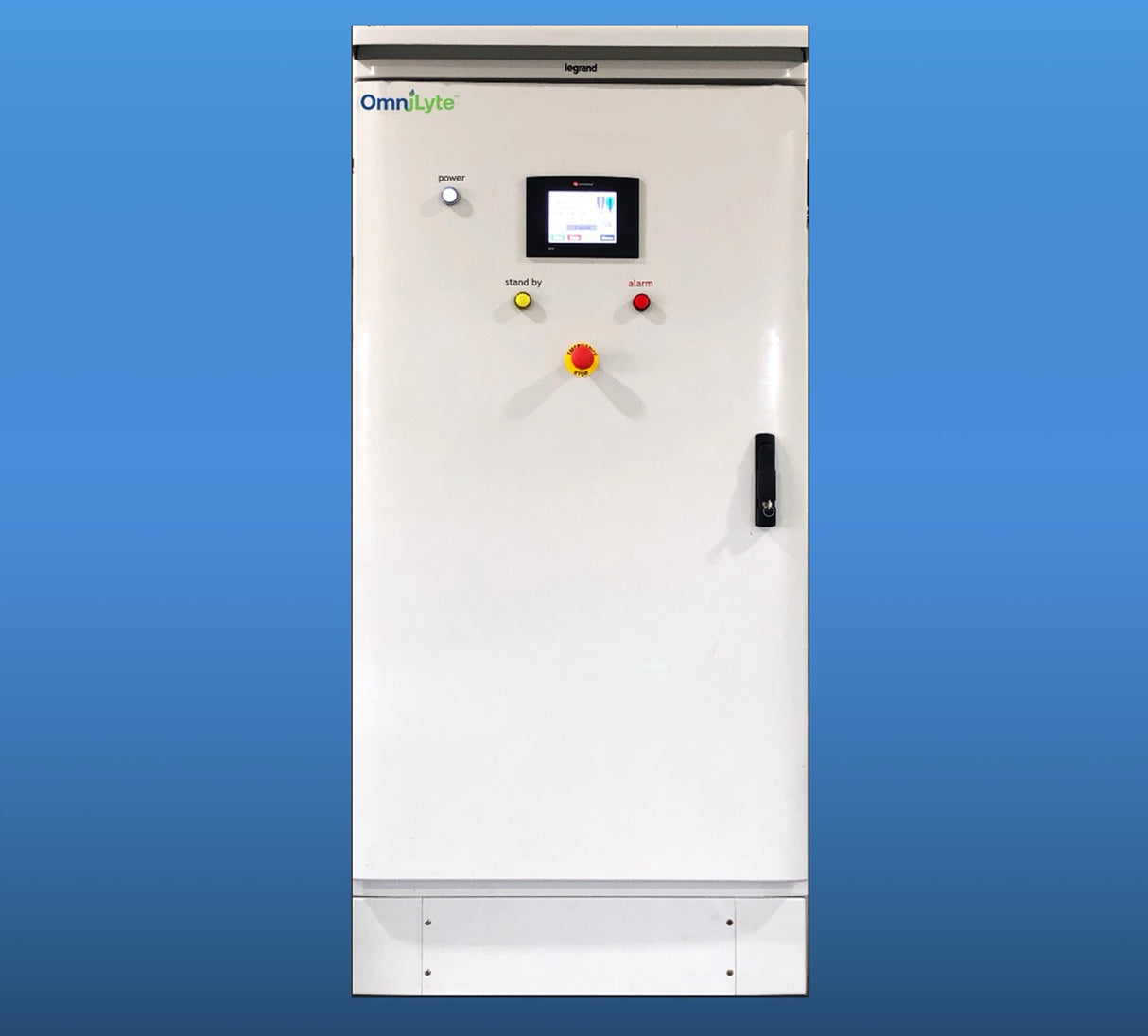

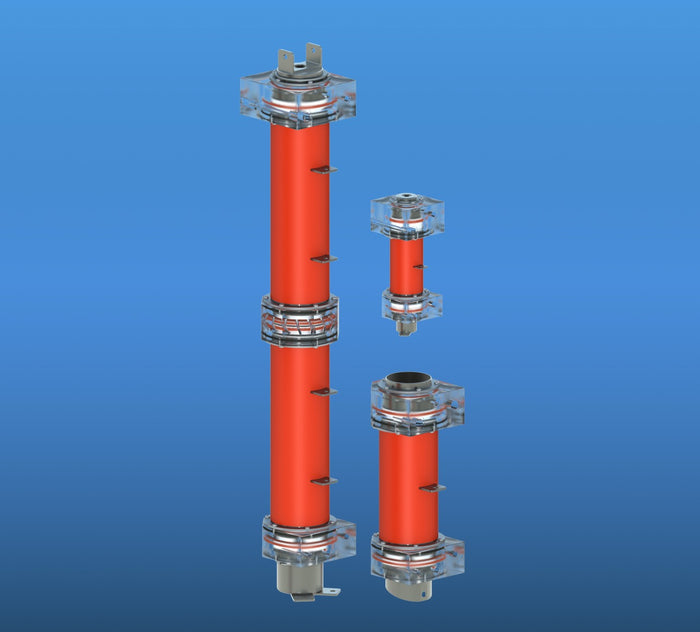

The OmniLyte ECO Ionizer Generator delivers clean, mineral-rich alkaline and acidic ionized water using precision-engineered Electro-Chemical Activation (ECA) technology. Available in three scalable models; ECO 1200, ECO 2400, and ECO 4800, this generator line offers flexible output capacities suited to bottled water producers, food processors, agricultural operations, and wellness facilities seeking safe, antioxidant-enhanced water.

Need a complete, high-capacity solution?

Check out the OmniLyte Pro 4800 ECO System — a full-scale alkaline ionized water production platform.

ECO Ionizer Generator - 300 is backordered and will ship as soon as it is back in stock.

ECO Ionizer Generator

Compact design, full-spectrum performance

Scalable Generator Options for a Variety of Applications

Choose from various models to match your production volume. Whether you’re bottling premium water, irrigating crops, or supporting clean water delivery in wellness or food production environments, the ECO Ionizer offers flexible capacity for evolving needs.

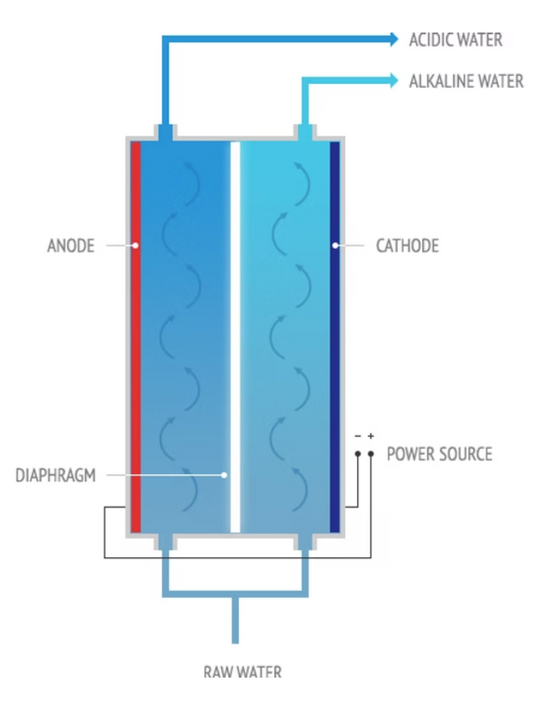

Advanced Electrochemical Alkaline Water Process

Combines anodic electrolytic oxidation and catalytic conversion of ionic compounds while preserving beneficial minerals — resulting in water that’s refreshing and higher hydration.

Built-In Cleaning and Long-Life Components

The generator includes an automatic self-cleaning cycle and durable electrodes coated in ruthenium, iridium, platinum, and titanium, ensuring optimal performance with minimal intervention.

Compact, Easy-to-Integrate Design

With its small footprint and plug-and-play configuration, the ECO Ionizer is ideal for retrofits, modular installations, or space-limited production areas.

Alkaline Water Applications for Many Industries

Features of ECA technology

Frequently Asked Questions

How does an alkaline water ionizer benefit my business?

How does an alkaline water ionizer benefit my business?

Alkaline water offers product diversification, supports higher profit margins, and helps meet rising consumer demand for clean, health-forward hydration across wellness, agriculture, and food sectors.

What makes OmniLyte’s generators different?

What makes OmniLyte’s generators different?

OmniLyte ECO Generators feature multi-stage purification, precious-metal coated electrodes, and ceramic diaphragm technology for unmatched output quality, consistency, and equipment longevity.

Can this generator support large-scale operations?

Can this generator support large-scale operations?

Yes. The ECO 4800 model supports high-output use cases. For even more capacity or integrated systems with tanks and advanced mineral control, consider the Pro 4800 ECO System.

What maintenance is required?

What maintenance is required?

- Self-cleaning cycles reduce buildup

- Regular inspection of electrodes and probes is advised

- System monitoring via the touchscreen helps identify anomalies early

- Filter changes (if applicable) ensure ongoing water quality

What are the typical pH and ORP levels of output?

What are the typical pH and ORP levels of output?

Alkaline water typically reaches pH 9–10 with low ORP (negative millivolt range). Acidic water falls between pH 2–5, making it suitable for cleaning or secondary process applications.