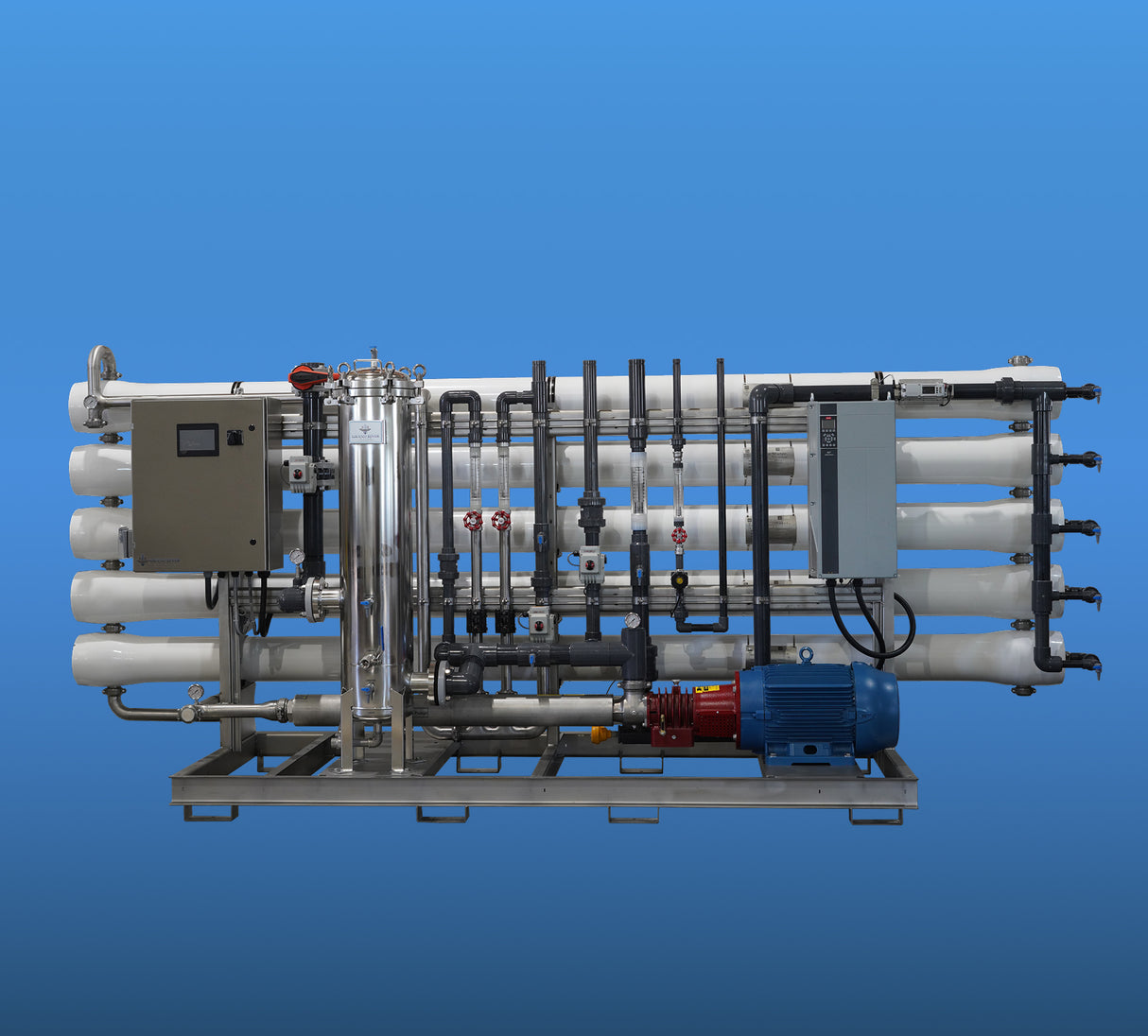

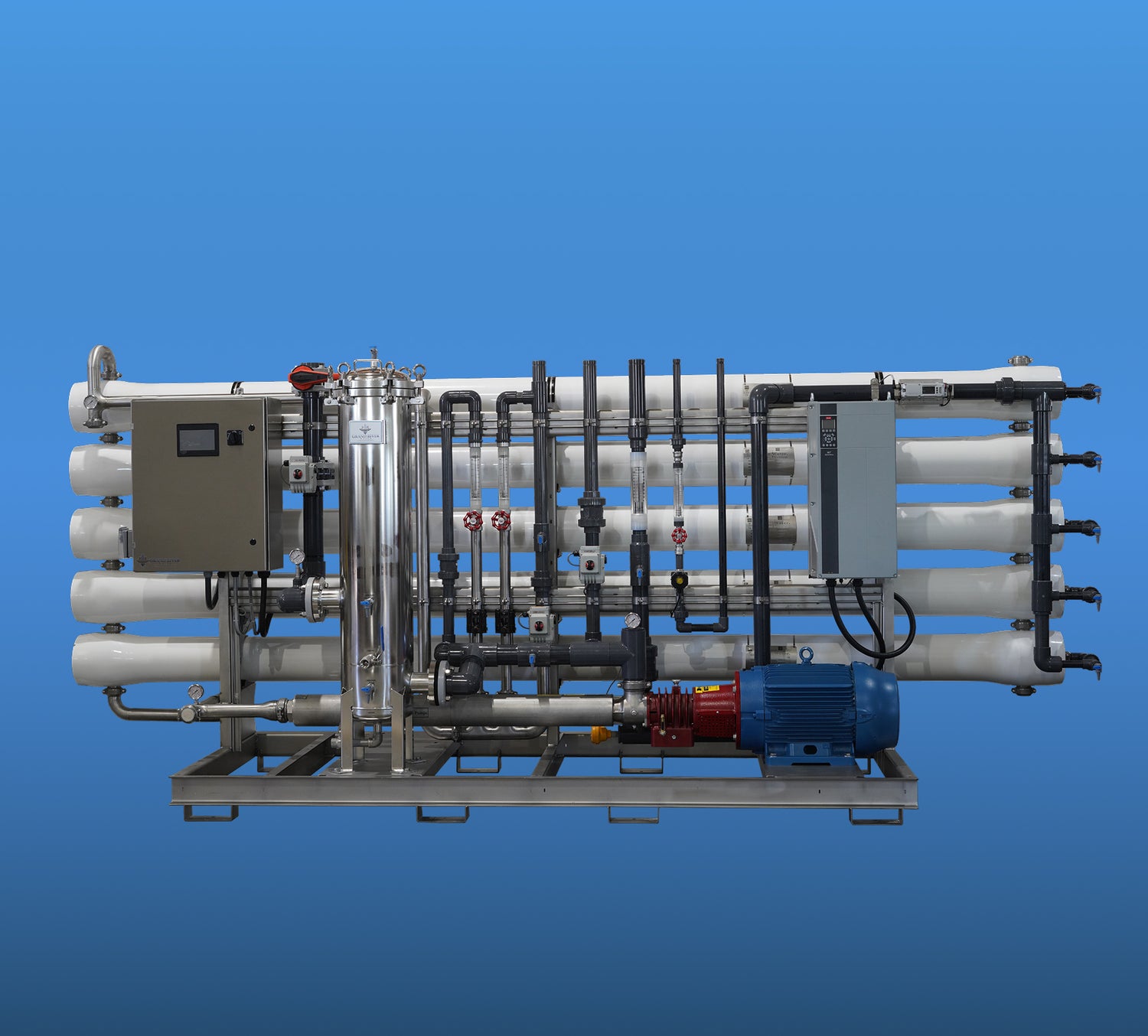

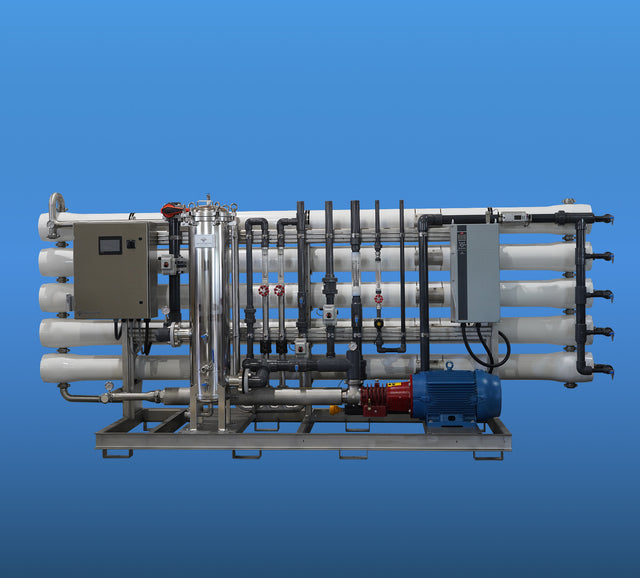

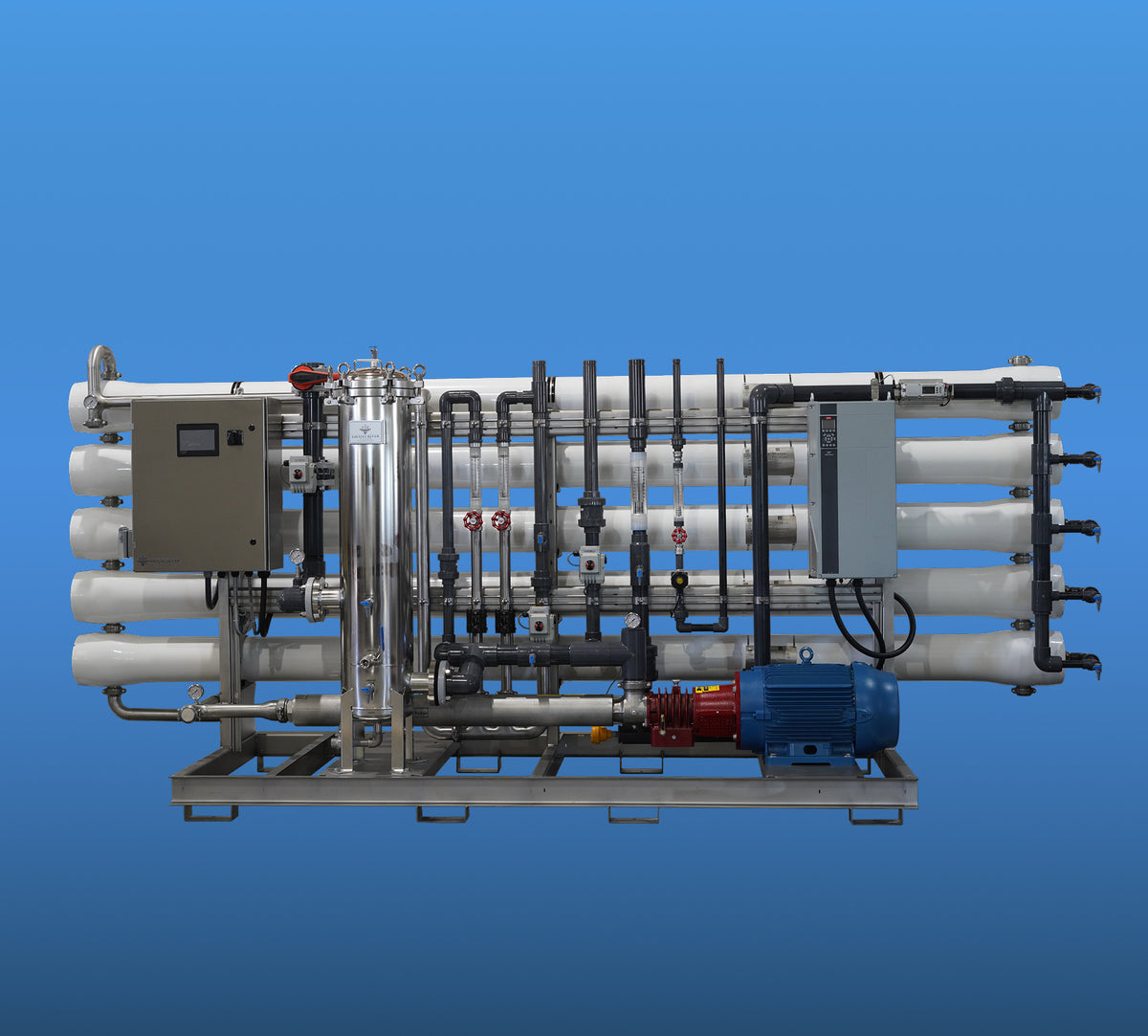

8H - HP Pro Series Reverse Osmosis System

(FOR STOCK AVAILABILITY, LEAD TIME, OR PRICING, PLEASE CALL +1 (800) 419-5707)

The OmniLyte 8H - HP (High Pressure) Pro Series Industrial Reverse Osmosis Systems are fully automated, high-performance "plug & play" solutions designed to economically deliver ultra-pure water. Built to handle demanding industrial environments, each system effectively removes dissolved minerals, bacteria, particles, and organic impurities while maintaining exceptional energy efficiency and durability. With output capacities ranging from 36,000 to 432,000 GPD, the 8H HP Pro Series supports larger-scale water treatment needs across diverse industries.

Skid-mounted, pre-piped, and pre-wired, these systems allow for fast installation and seamless startup—so you can stay focused on operations, not equipment setup.

8H - HP Pro Series Reverse Osmosis System - 8H-HP Pro is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

8H - HP Pro Series Reverse Osmosis System Features

High-pressure performance, high-purity output, and fully integrated automation for reliable operation and maximum ROI.

Exceptional Output for Demanding Applications

Delivers up to 432,000 gallons per day—perfect for large-scale commercial, agricultural, and manufacturing environments requiring high-purity water.

Rapid Setup, Minimal Downtime

Skid-mounted and factory preassembled for quick "plug & play" installation, reducing time and costs during integration.

Built for Performance and Longevity

Designed with 316SS Tonkaflo multistage pump, FRP membrane housings, and smart VFD pump control to ensure efficient and long-lasting performance.

Industrial Intelligence at High Pressure

Integrated Horner PLC with Smart-Rail remote I/O, VFD pump control, and conductivity sensors deliver reliable, around-the-clock automation for consistent water quality and optimized performance.

Specifications

High-Volume, High-Purity Water for Many Industries

Features of ECA technology

Frequently Asked Questions

What’s the daily water output capacity of the 8H - HP Pro Series?

What’s the daily water output capacity of the 8H - HP Pro Series?

It ranges from 36,000 to 432,000 gallons per day, depending on model configuration.

What operating pressure range does the system support?

What operating pressure range does the system support?

Between 120–450 psi, engineered for high-demand reverse osmosis performance.

Can this system be installed quickly?

Can this system be installed quickly?

Yes. The 8H - HP Pro is fully skid-mounted, pre-wired, and pre-piped for fast deployment.

What kind of monitoring does the system include?

What kind of monitoring does the system include?

The system includes a Horner PLC with remote I/O, flow transmitters, pressure sensors, and a product water conductivity transmitter.

What types of environments is it best suited for?

What types of environments is it best suited for?

Ideal for commercial, agricultural, and industrial applications including cooling, bottling, livestock operations, and more.