OmniLyte ELA Series Generators

(FOR STOCK AVAILABILITY, LEAD TIME, OR PRICING, PLEASE CALL +1 (800) 419-5707)

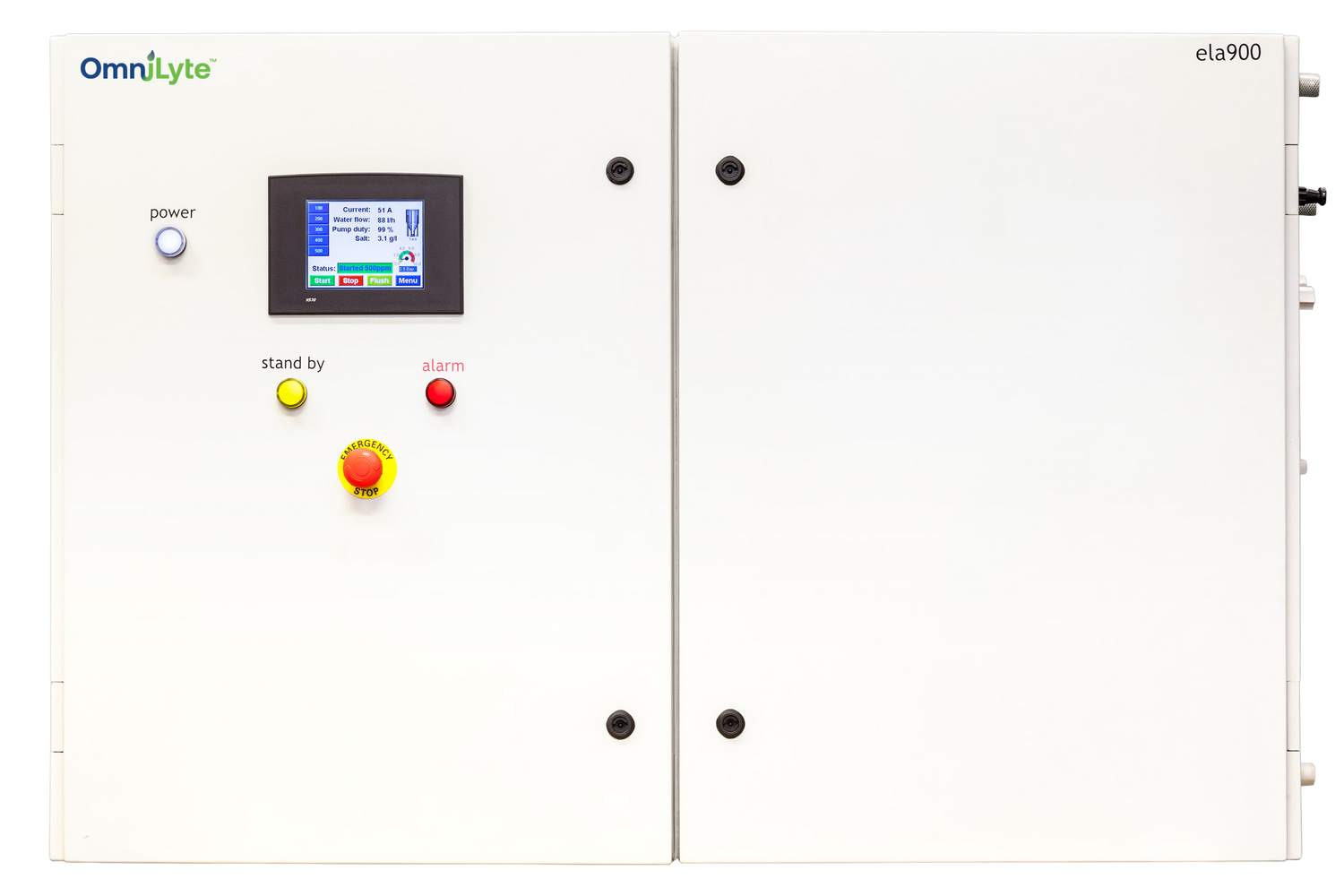

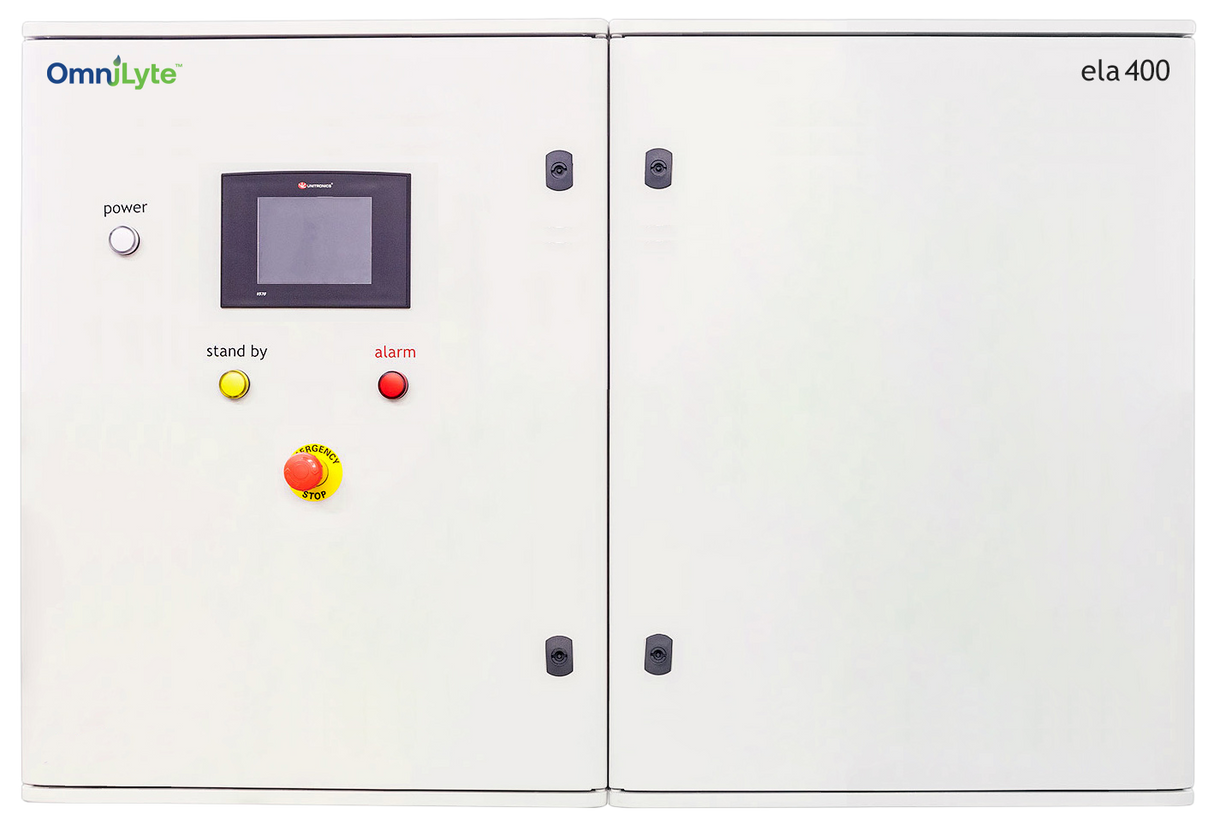

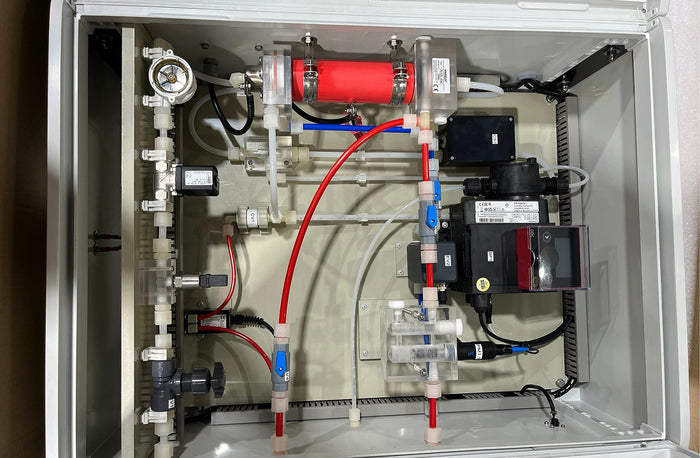

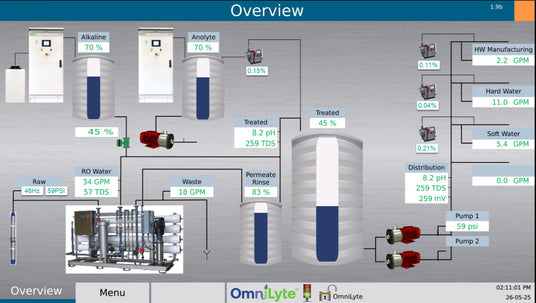

The ELA Series of Generators are a fully automated anolyte water treatment system designed for large-scale disinfection. The system offers simplicity and ease of operation.

Various models are available that are capable of producing up to 600 liters per hour of Neutral Anolyte, with the option to adjust PH in the range of PH ~5.0 - 8.5. These units provide rapid, high-output disinfection for applications such as municipal water treatment, agriculture, livestock, healthcare, and hospitality facilities.

OmniLyte ELA Series Generators - ELA-200 is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

ELA Anolyte Generator features

The ELA Anolyte Generators deliver high-volume, automated anolyte production, ensuring large-scale sanitation.

Fully Customizable Concentrations

Operators can adjust chlorine concentration from 100 to 500 ppm, ensuring precise dosing for specific applications.

User-Friendly PLC Automation

The touchscreen PLC control panel allows operators to easily adjust settings, monitor output, and optimize system performance with minimal training.

Flexible Operation

With wall-mount and floor-standing options, the ELA generators are designed for easy integration into diverse environments.

Specifications

Disinfecting Solutions for Many Industries

Features of ECA technology

Frequently Asked Questions

How do ELA generators maintain solution quality?

How do ELA generators maintain solution quality?

The system allows for adjustment of active chlorine concentration by setting the current, ensuring the anolyte meets specific disinfection needs with concentrations typically ranging between 500-700 mg/L.

What is Electrochemical Activation (ECA) technology?

What is Electrochemical Activation (ECA) technology?

ECA technology involves passing a diluted salt solution through an electrolytic cell, producing two solutions: anolyte and catholyte. Anolyte serves as a disinfectant, while catholyte functions as a mild cleaning agent.

How does the generator ensure consistent anolyte quality?

How does the generator ensure consistent anolyte quality?

The system allows for precise adjustment of active chlorine concentrations and pH levels, ensuring the anolyte meets specific disinfection requirements for various applications.

What are the safety considerations when using anolyte produced by ELA generators?

What are the safety considerations when using anolyte produced by ELA generators?

Anolyte is non-corrosive and non-hazardous to handle, creating a safer work environment. It eliminates the need for specialty storage of dangerous chemicals and is harmless to the environment.