ELA ANW Anolyte Generators

(FOR STOCK AVAILABILITY, LEAD TIME, OR PRICING, PLEASE CALL +1 (800) 419-5707)

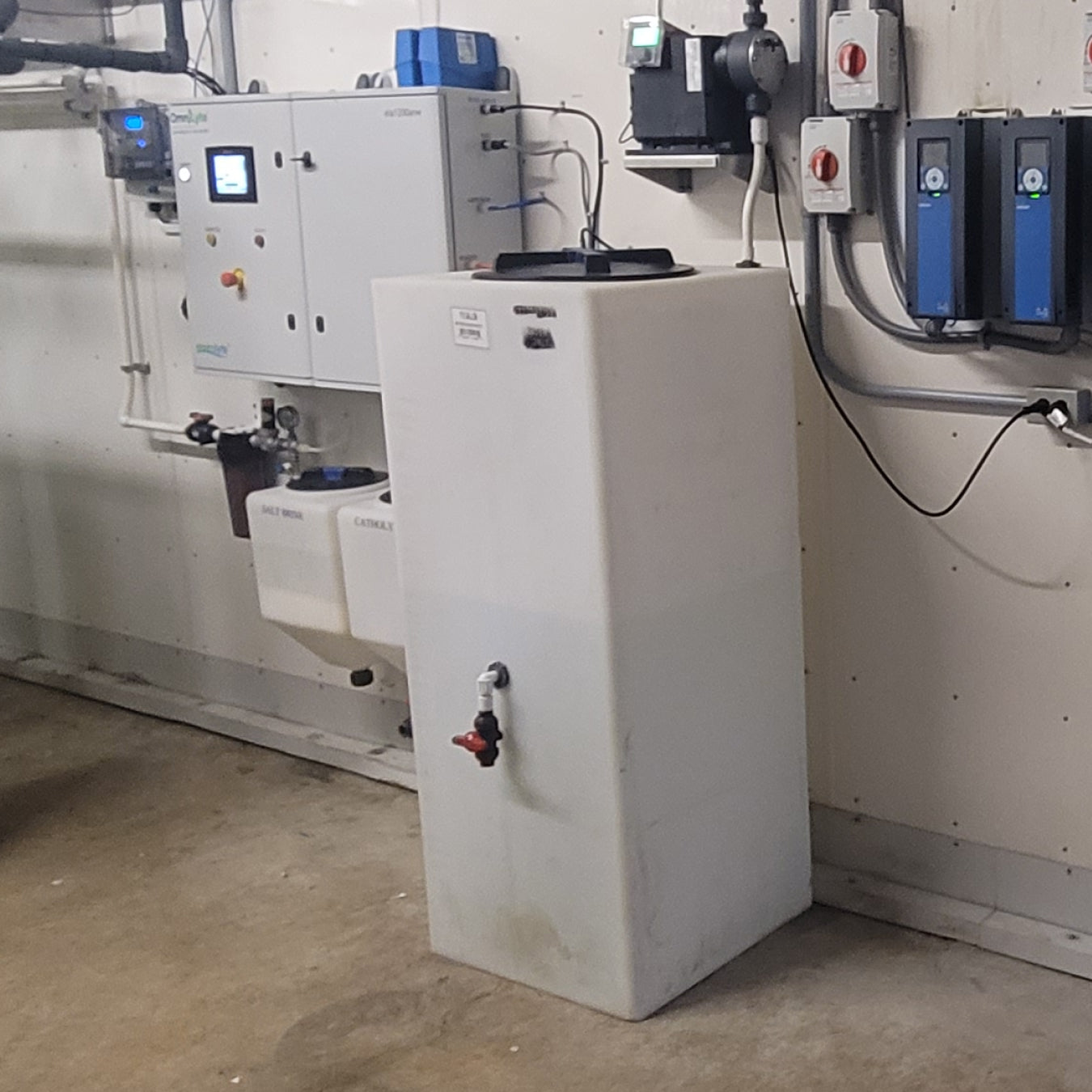

The ELA ANW Anolyte Generators are designed to provide high-volume, low-residue disinfection solutions with minimal salt and energy consumption. These anolyte generators produce highly effective, eco-friendly disinfection solutions for industries that need to adhere to high sanitation standards. With models ranging from 20 to 6,000 liters per hour, the ELA ANW series offers a cost-effective, scalable water treatment solution. These generators are ideal for municipal water applications, industrial facilities, and healthcare settings.

ELA ANW Anolyte Generators - ELA-400ANW is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

ELA ANW Anolyte Generator features

These anolyte generators provide high-output production with ultra-low salt and energy consumption, making them ideal for industries requiring effective sanitation with minimal corrosion.

High Production Capacity

With capacity up to 1,800 liters of Neutral Anolyte per hour, these are ideal for large-scale disinfection needs. This high-output ensures consistent, on-demand supply for critical sanitation or water treatment applications.

Low Chlorine Residue

Achieve effective sanitation without excessive chlorides that can cause corrosion. Ideal for industries such as food processing, cooling tower disinfection, and municipal water treatment. Anolyte generators minimize chloride residue while still being a powerful disinfectant. Users can easily modify the active chlorine concentration of the Anolyte by adjusting the electrical current settings, allowing flexibility to meet specific disinfection requirements.

Efficient Resource Utilization

Uses only 1.5 grams of NaCl and 4 watts of energy per liter of anolyte produced for superior efficiency. This makes the generators ideal for applications where minimizing salt residue and energy usage is crucial.

Fully Automated Operation with Ethernet Remote Access

Automatic start and stop functions optimize energy use and reduce manual intervention. Built-in level switches in the anolyte storage tank ensure seamless and efficient performance.

Specifications

The ELA-ANW series generators are available in models with differing output capacities to meet various needs.

Disinfecting Solutions for Many Industries

Features of ECA technology

Frequently Asked Questions

What distinguishes the ELA-ANW Series from standard anolyte generators?

What distinguishes the ELA-ANW Series from standard anolyte generators?

The ELA-ANW Series is engineered to produce anolyte using significantly less salt and energy—approximately 1.5 grams of NaCl and 4 watts of energy per liter, which is 5 and 2.5 times less, respectively, than standard ELA machines.

Can the pH level of the anolyte be adjusted in the ELA-ANW Series?

Can the pH level of the anolyte be adjusted in the ELA-ANW Series?

Yes, while the standard pH of anolyte produced is around 7.5, the system can be optionally configured to adjust the pH range between 2.5 and 7.5, depending on specific application requirements.

Is catholyte produced as a by-product in the ELA-ANW Series?

Is catholyte produced as a by-product in the ELA-ANW Series?

No, unlike standard anolyte generators, the ELA-ANW Series does not produce catholyte in commercially viable volumes, making it ideal for applications where only anolyte is needed.

What is anolyte, and how is it produced?

What is anolyte, and how is it produced?

Anolyte is a powerful disinfectant solution generated through Electrochemical Activation (ECA) technology. By passing a diluted salt solution through a specialized electrolytic cell, the process produces anolyte in the anode chamber and catholyte in the cathode chamber.

Is anolyte safe for use in organic agriculture?

Is anolyte safe for use in organic agriculture?

Yes, anolyte is approved for use in organic agriculture. It effectively eliminates biofilms, algae, and pathogens without leaving harmful residues, making it an eco-friendly solution for irrigation systems.

Can microorganisms develop resistance to anolyte over time?

Can microorganisms develop resistance to anolyte over time?

No, studies have shown that microorganisms do not develop resistance to anolyte, even with prolonged use. This makes it a reliable and long-term disinfection solution.